Positive Train Control (PTC) for Safer, More Efficient Railways

Understanding the Systems That Prevent Collisions and Enforce Train Safety

When talking about safety, Positive Train Control (PTC) has emerged as a transformative technology. Designed to prevent train collisions, derailments due to excessive speed, unauthorized train movements in work zones, and movement of trains through switches left in the wrong position, PTC has become the gold standard in railway safety. Its implementation not only enhances safety but also boosts productivity, making it a cornerstone of modern rail operations.

Understanding the Main Components of PTC

1. Onboard Locomotive Equipment

PTC systems are equipped with onboard computers, GPS receivers, radios, and other necessary hardware. These components continuously monitor train movements and communicate with wayside infrastructure to ensure safe operations.

2. Wayside Infrastructure

Wayside infrastructure includes signals, switches, antennas, and base stations strategically placed along the rail network. These components communicate with onboard systems to relay critical information and commands, such as speed limits and track conditions.

3. Back Office Servers

The back-office servers work as the brain of the PTC system. They process data from onboard and wayside components, analyze train movements in real-time, and issue commands to ensure safe operations. Additionally, these servers store vast amounts of historical data for analysis and future optimizations.

4. Communications Network

A robust and reliable communications network is crucial for the seamless operation of PTC systems. This network facilitates real-time data exchange between onboard, wayside, and back-office components, enabling quick decision-making and enhancing overall system efficiency.

Why PTC is Becoming a Standard in the Rail Industry

1. Enhanced Safety

PTC significantly reduces the risk of accidents by continuously monitoring train movements and intervening when necessary. Its ability to enforce speed limits, prevent collisions, and protect workers in construction zones has made it an indispensable tool for ensuring passenger and crew safety.

2. Improved Efficiency

By optimizing train movements and reducing the likelihood of delays caused by accidents or human error, PTC enhances operational efficiency. This leads to fewer disruptions, faster transit times, and ultimately, improved customer satisfaction.

3. Regulatory Compliance

Following several high-profile accidents, regulatory bodies have mandated the implementation of PTC on major railroads across the United States. This regulatory push has accelerated the adoption of PTC, making it a standard practice in the industry.

4. Cost Savings

While the initial investment in PTC implementation can be significant, the long-term benefits far outweigh the costs. By minimizing the risk of accidents and associated liabilities, PTC helps railroads save money through reduced insurance premiums and legal expenses.

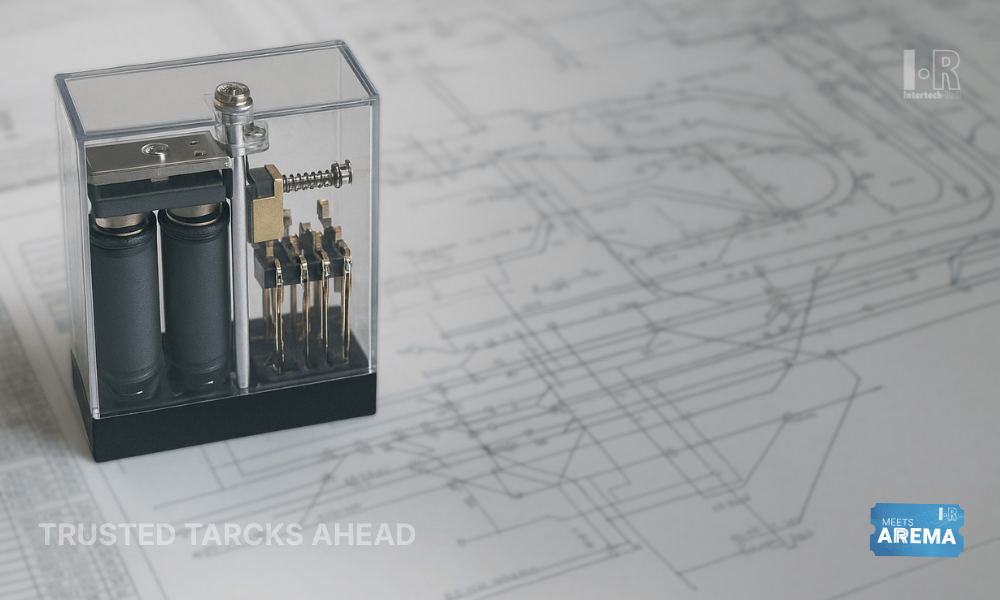

The Role of the Balise System in PTC

Among the various components of PTC, the balise system plays a crucial role in ensuring accurate train positioning and reliable communication with onboard equipment. Balises, typically installed along the track, transmit vital information such as speed limits, track occupancy, and switch positions to passing trains. This real-time data exchange enables onboard systems to make informed decisions and promptly implement safety measures.

The balise system's ability to provide precise location information is particularly valuable in scenarios where GPS signals may be unreliable, such as tunnels or urban environments with tall buildings. Additionally, its low-profile design minimizes the risk of damage and ensures uninterrupted operation in all weather conditions.