Articles

Latest Articles

Categories

August 8, 2025

Train braking systems have come a long way—from manual levers to advanced electronically controlled pneumatic (ECP) solutions. In this article, we explore how braking technology ensures safe, reliable, and efficient train operations across freight and passenger networks. Learn about pneumatic, dynamic, and regenerative

March 8, 2023

Train crashes are a tragic event that can have devastating consequences. Usually are thousands of tons of metal in motion (sometimes in high speed) when it happens. These accidents can occur for a variety of reasons, including human error, mechanical failure, and environmental factors. Human Error One of the most common reasons for train crashes is human error. This can include mistakes made by the train operator, miscommunication between personnel, or failure to follow safety protocols. Train operators are required to undergo extensive training and follow strict safety guidelines to ensure the safety of their passengers and the public. However, even the most experienced operators can make mistakes, and these mistakes can lead to serious accidents. To prevent human error, train operators must be diligent in following safety protocols and receive regular training to keep their skills up to date. Additionally, advanced safety technology, such as automatic braking systems, can help to prevent accidents caused by human error. Mechanical Failure Another common reason for train crashes is mechanical failure. This can include issues with the brakes, engine, or other critical components of the train. Mechanical failures can occur due to poor maintenance, manufacturing defects, or wear and tear over time. When these failures occur, the train can lose control and collide with other trains or obstacles. To prevent mechanical failures, trains must undergo regular maintenance and inspections to ensure that all components are functioning correctly. Manufacturers must also take responsibility for the quality of their products and ensure that they are designed and built to the highest safety standards. Equipment such as Hot Box , Wheel Sensor , Track Scanner are mandatory in the inspections and maintenance procedures Environmental Factors Environmental factors can also contribute to train crashes. This can include weather conditions such as heavy rain, snow, or fog, which can reduce visibility and make it difficult for train operators to see obstacles in their path. Additionally, natural disasters such as landslides or earthquakes can damage tracks and cause derailments . To prevent accidents caused by environmental factors, train operators must be trained to adapt to changing conditions and adjust their driving to suit the weather or other environmental factors. Train companies must also invest in infrastructure improvements, such as improved drainage systems or reinforced tracks, to prevent damage caused by natural disasters. Sabotage or Terrorism Finally, train crashes can also be caused by acts of sabotage or terrorism. These deliberate acts of violence can have devastating consequences, both for the train passengers and the wider community. While it is impossible to predict and prevent all acts of sabotage or terrorism, train companies can take steps to improve security and prevent unauthorized access to train tracks and equipment. SAFETY! By investing in safety technology, regular maintenance and inspections, and improved security measures, train companies can help to prevent these accidents and keep their cargo and passengers safe.

Level Crossing

February 27, 2025

Level crossings are essential to railway networks but also present significant safety challenges. This article explores the latest innovations in train detection, automated barriers, and warning systems that enhance safety and efficiency. Learn how cutting-edge technologies, such as AI-driven monitoring and fail-safe detection, are shaping the future of railway operations.

Read more to discover the best solutions for safer and more efficient level crossings.

March 1, 2023

Level crossings are an essential component of the railway infrastructure, serving as a connection between roads and railway tracks. The purpose of a level crossing is to allow road users to cross the tracks safely , with minimal disruption to the rail traffic. The choice of material used for a level crossing surface is crucial for ensuring the safety of road users and rail passengers. The two most used materials for level crossings are rubber plaques and asphalt. Importance of Choosing the Right Material for Level Crossing Surfaces Choosing the right material for level crossing surfaces is of utmost importance due to its significant impact on the safety of road users and rail passengers. The surface material plays a crucial role in providing traction and minimizing the risk of accidents. Additionally, it should withstand heavy loads and endure various weather conditions to ensure long-term durability. Environmental considerations also come into play, as the material should be sustainable and minimize negative impacts on the environment. Making a well-informed decision regarding the choice of material is essential to create level crossings that are safe, reliable, and environmentally conscious. Rubber Plaques: Durability, Safety, and Environmental Benefits Rubber plaques are made from recycled tires and are a popular choice for level crossings because of their durability and safety features. Rubber plaques provide a high level of traction for vehicles and pedestrians, reducing the risk of accidents. They are also less likely to crack or become damaged compared to asphalt, which can cause tripping hazards and damage to vehicles. In addition to their safety benefits, rubber plaques are also more environmentally friendly than asphalt. They are made from recycled tires, which reduces the number of tires that would otherwise end up in landfills. Furthermore, they do not emit harmful chemicals or fumes, making them a safer option for the environment.

December 12, 2022

We all know the importance of a level crossing when a railway track crosses a road or street. In this type of situation, there is hardware behind it with all the security issues that we have already addressed in other articles on this blog, such as FAIL-SAFE features (any problem in the system, put it in a non-accident situation) and even very low-level failures (SIL3, SIL4). What few people know are the floors of these level crossings. When a road crosses a rail, asphalt or concrete can be placed, which is done at 99 out of 100 crossings. However, over time, this floor does not support the vibration that exists inside a railroad with a freight train passing by all the time, or even in cities, with urban trains. In a few months, asphalt becomes brittle and destroys itself, just like concrete. A few years ago, it was developed as a perfect solution, already adopted in developed countries, which are vulcanized rubber floors. They are formed by modules of vulcanized rubber that fit together forming a floor that is often more resistant than asphalt and concrete and does not suffer from the vibration characteristic of a highway. This type of floor often supports off-road vehicles in mining companies with loads of up to 300 tons, believe it or not. And its duration is set for 10 to 30 years of life, which is extremely high considering its asphalt and concrete competitors. In underdeveloped countries this type of solution is not used and most of the time asphalt or stones are simply placed to make the crossing works. With vibration this material is quickly dispersed. A railroad track profile is half a foot or 15 centimeters on average and if there is nothing at the intersection an ordinary car cannot pass a railroad track without damaging its wheels. So, the advantages of this type of flooring are enormous, mainly in terms of loads, durability, vibration resistance, weather conditions such as rain, floods. And yet this type of rubber flooring normally uses a surface with different triangular patterns that greatly increase the resistance to adhesion of both tires and pedestrians, being compared to the same type of adhesion of asphalt and are more efficient in water drainage. This type of material has been more widespread in recent years and the trend is that all level crossings will have this type of solution in the coming decades, which is even sustainable in the sense that old tires are ground and reused in the manufacture of these floors which in their composition normally use up to 80% recycled rubber ranging from 80 to 50% recycled rubber, the rest is natural rubber and some components that increase the material's hardness and resistance. Normally, the rubber floor in modules for level crossings is quickly assembled with a team of few operators and a forklift is enough for the whole system to be operational in a few hours. This type of flooring is adaptable to the ground and is placed on the rail sleepers, spreading the load of the truck that is crossing the track, avoiding damage to the rails or movement of the rails during the passage of a heavy-duty vehicle, for example. This type of solution is highly recommended, easily installable and gigantic durability, especially when heavy vehicles are used. It is also used for crossing pedestrians and bicycles due to its high adherence. In the landscape it is usually suitable because its characteristic color is like the color of asphalt and has a very important environmental aspect in the recycling of rubber used in tires, mainly tires for off-road vehicles, which represents a huge environmental problem for many mining companies. This would be one of the main applications of this type of solution. Maintenance is also very simple: any of these modules that present a problem can be easily replaced. The rubber floor is a solution that's here to stay and is set to replace all asphalt and concrete solutions worldwide on thousands of level crossings. The environment appreciates. Read more: Vital Signaling: technology that propels the production and the railway transportation of ore Brazil on the tracks: Railway Landmark and sustainability get advancements in the domestic market

November 3, 2022

A railway train easily carries thousands of tons of metal, only one car can carry 120 tons and it is very common with positions of 100, 200, 300 freight cars. This type of composition takes, with emergency braking, almost 2 kilometers to brake at an average speed of 50 kilometers per hour. So, it is critical that in your movement, nothing can be ahead. Any object in front of such a composition will be destroyed, nothing survives. So, that's why trains run freely through all countries, and the idea is that these railways have bridges or passages underneath so that the train never has to stop before its destination. However, there are critical situations where there is a road crossing with a railroad and it was not possible to make this crossing through a bridge or a tunnel. In this case, there is what we call a level crossing or level crossing. In the past, these systems worked with a railway guard who watched the train approach. At the right moment, the whistle sounded and manually lowered the vehicle gate using a crank, pressed a button and light signals began to flash for the cars that were supposed to stop and wait for the train to pass. This went on for decades and decades. However, about 50 years ago, the automatic systems of gates or level crossings were introduced, which are basically the ones that are used today. These are fail-safe systems, where any electrical problem or cable breakage or excessive rain, any problem at all, the barrier for vehicles is in the lowered position avoiding accident. Whenever there is a problem, he gets into a safe position. They are fail safe systems. There are three types of automatic level crossing technology: First level crossing option: The first, the most traditional, is with track circuit, where the rails are used as a kind of electrical circuit and the voltage in these sections is measured and when any heavy rolling stock enters that section, an identification is made and this section of track next to the level crossing, the process of warning cars that a train is approaching begins and the entire process of closing the barrier begins, luminous signals and bells . Then, when the train passes through this circuit and enters the next track circuit, after the level crossing, the barrier is opened again. The other technology uses what we call axis sensors. An axle sensor (fail safe) identifies the axle of the locomotive on approach to the level crossing. Second level crossing option: It is strategically placed at a safe distance, based on the maximum speed the train travels on that stretch. And when the train passes through that point, the process of alarming the level crossing bells and the light signals begins, both for the car and for the conductor. Normally, 20 seconds of signals and alarms are expected and within 10 seconds for the composition to arrive at the level crossing, the barrier begins to lowe . These times vary from country to country. The axles are counted on that axle sensor and when the train starts to pass through an axle sensor right after the level crossing, that same axle sensor sends the information for a micro - controlled system that checks if all axes that passed the initial identification passed after the level crossing. It is the certainty that the entire composition has already passed to start the ascent of the barrier and the passage of cars and pedestrians is released. Third level crossing option: There is a third type of more sophisticated level crossing that predicts the speed of the train and adjusts the opening and closing time of barriers and audible signals based on the speed at which the train is approaching, but there are fewer and much lower-level barriers. more costly. The level crossing has a regulation in each country with light and sound signals and signs like the famous “stop, look , listen” . There is also the Saint Andrew cross (usually with the words “railway crossing”. It has a whole symbology so that this system is as safe as possible. Anyway, it is an old technology, but very robust and that avoids many accidents around the world. A train at 50, 60 km per hour hitting a vehicle is not a pleasant sight. There are millions of level crossings in the world, and it is estimated that only 30% of them are automatic. Many are still manual. Mainly level crossing in remote locations, away from cities, close to indigenous villages, which greatly increases the danger of accidents. Governments are putting more and more regulations in place to automate and monitor these level crossings. in monitoring it is not possible to automatically command to open or command to close a level crossing. However, you can see the status and verify if all are operating normally. That's what exists behind a simple level crossing, a great technology, even an old one, but it represents enormous security. Read more: Vital Signaling: technology that propels the production and the railway transportation of ore Brazil on the tracks: Railway Landmark and sustainability get advancements in the domestic market

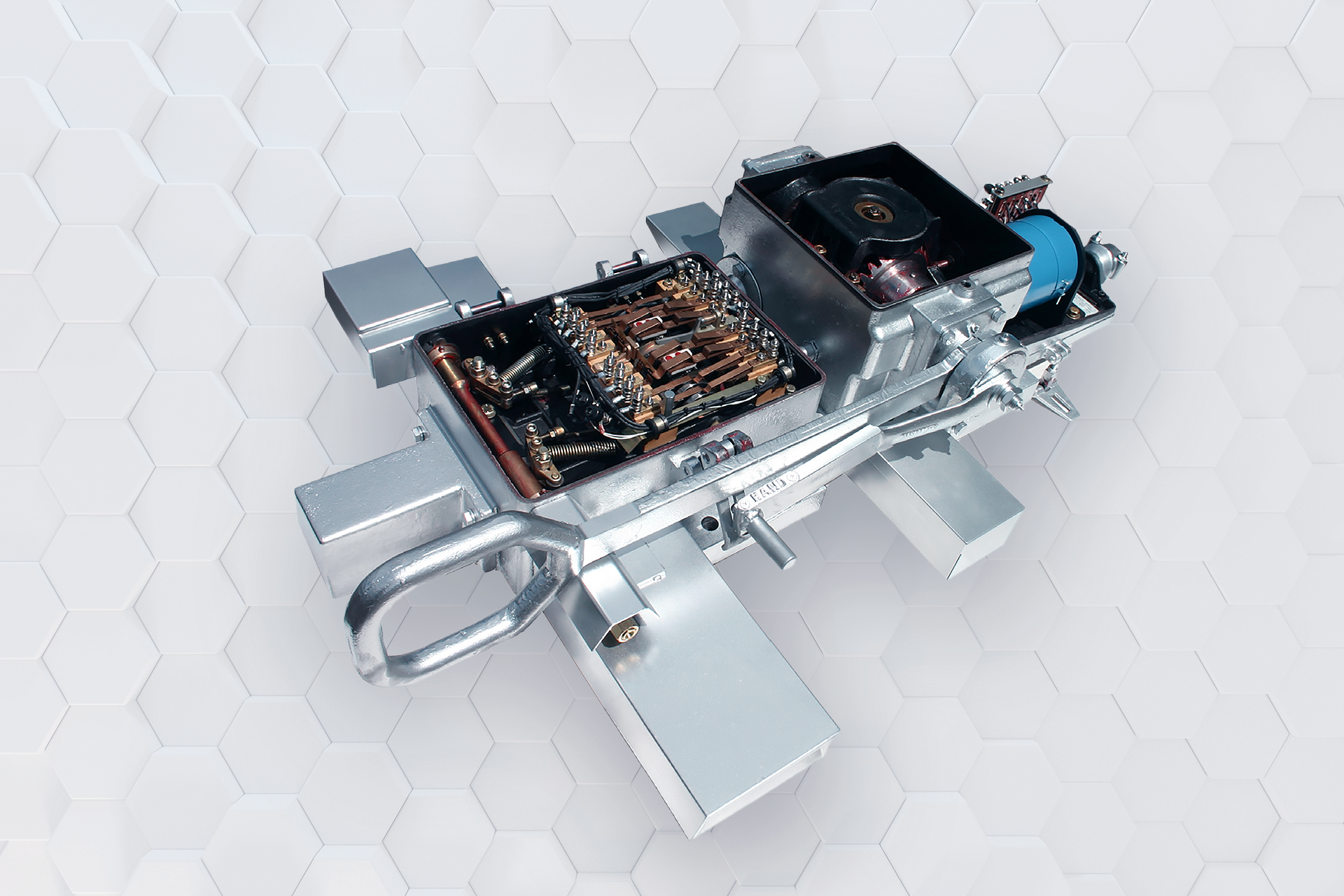

Switch Machine

February 23, 2023

Fail-safe relays play a crucial role in ensuring the safety and reliability of railway systems. These devices are designed to prevent accidents, equipment failures, and malfunctions in railway applications by detecting and reacting to fault conditions. In this article, we will explore the importance of fail-safe relays in rail applications and how they help to ensure the safe and efficient operation of railway systems. Reliability and Safety Fail-safe relays are designed to provide reliable protection against potential faults and failures in railway systems. These devices are equipped with sensors that detect and respond to fault conditions, such as over-current, over-voltage, and short-circuit situations. Once a fault is detected, the relay will trigger an alarm or shut down the system to prevent damage or a potential accident. This helps to ensure the safe and efficient operation of the railway system, reducing the risk of downtime and improving reliability. Protection of Equipment and Infrastructure Railway systems are complex and sophisticated, comprising of various components such as track switches , signals , power supplies, and rolling stock. Fail-safe relays play a crucial role in protecting this equipment and infrastructure by detecting and reacting to fault conditions. For example, if an over-current situation is detected, the relay will trigger an alarm, alerting maintenance personnel to take action and prevent damage to the equipment. This helps to extend the lifespan of railway equipment, reducing the need for costly repairs and replacements.

Signaling

August 8, 2025

Train braking systems have come a long way—from manual levers to advanced electronically controlled pneumatic (ECP) solutions. In this article, we explore how braking technology ensures safe, reliable, and efficient train operations across freight and passenger networks. Learn about pneumatic, dynamic, and regenerative

February 23, 2023

Fail-safe relays play a crucial role in ensuring the safety and reliability of railway systems. These devices are designed to prevent accidents, equipment failures, and malfunctions in railway applications by detecting and reacting to fault conditions. In this article, we will explore the importance of fail-safe relays in rail applications and how they help to ensure the safe and efficient operation of railway systems. Reliability and Safety Fail-safe relays are designed to provide reliable protection against potential faults and failures in railway systems. These devices are equipped with sensors that detect and respond to fault conditions, such as over-current, over-voltage, and short-circuit situations. Once a fault is detected, the relay will trigger an alarm or shut down the system to prevent damage or a potential accident. This helps to ensure the safe and efficient operation of the railway system, reducing the risk of downtime and improving reliability. Protection of Equipment and Infrastructure Railway systems are complex and sophisticated, comprising of various components such as track switches , signals , power supplies, and rolling stock. Fail-safe relays play a crucial role in protecting this equipment and infrastructure by detecting and reacting to fault conditions. For example, if an over-current situation is detected, the relay will trigger an alarm, alerting maintenance personnel to take action and prevent damage to the equipment. This helps to extend the lifespan of railway equipment, reducing the need for costly repairs and replacements.

RFID

June 14, 2025

Discover the key differences between RFID and Beacon balise technologies used in railway systems. Understand how each functions, their pros and cons, and why RFID continues to stand out as a reliable, low-maintenance solution for critical rail operations—especially in harsh or remote environments.

Intertech News

By Erika Souza

•

April 28, 2023

Railway systems have been an integral part of transportation infrastructure for centuries. They are not only important for the transportation of goods and people, but also for their impact on economic growth and development. In this article, we will take a look at the biggest railways in the world, in terms of distance. Trans-Siberian Railway The Trans-Siberian Railway is the longest railway in the world, spanning a distance of 9,289 kilometers (5,772 miles). It connects Moscow in Russia to Vladivostok, a major port city on the Pacific Ocean. The railway was built between 1891 and 1916, and it remains an important transportation link in Russia and Asia. The journey from Moscow to Vladivostok takes approximately 6 days and offers stunning views of the Russian countryside. Trans-Canadian Railway The Trans-Canadian Railway is the second-longest railway in the world, spanning a distance of 7,821 kilometers (4,860 miles). It runs from Vancouver on the west coast of Canada to Halifax on the east coast. The railway was built between 1881 and 1885, and it was a major factor in the development of Canada as a nation. The journey from Vancouver to Halifax takes approximately 4 days and offers breathtaking views of the Canadian Rockies. Trans-Mongolian Railway The Trans-Mongolian Railway is a 1,110-kilometer (684-mile) railway that connects Moscow in Russia to Ulaanbaatar in Mongolia, and then on to Beijing in China. The railway was built between 1949 and 1961, and it is an important transportation link between Russia, Mongolia, and China. The journey from Moscow to Beijing takes approximately 6 days and offers stunning views of the Gobi Desert. Indian Railways Indian Railways is the fourth-largest railway system in the world, with a total route length of 68,155 kilometers (42,350 miles). It is also the largest railway system in Asia and operates over 20,000 passenger and freight trains daily. The railway was founded in 1853 and has played a crucial role in the development of India's economy. The railway connects all major cities in India, from the Himalayas in the north to the Indian Ocean in the south. US Railways The United States has the fifth-largest railway system in the world, with a total route length of 250,000 kilometers (156,000 miles). The railway system plays a crucial role in the transportation of goods and people in the US, with over 40% of all freight in the US transported by rail. The railway system was built in the 19th century and played a crucial role in the industrialization of the US.

March 17, 2023

The locomotive industry has been working tirelessly to find new, innovative solutions to fuel their trains. As the world moves towards a more sustainable future, it is imperative that the locomotive industry also adapts to meet these changes. In recent years, several technologies have been developed and tested in locomotive fuel, and in this article, we will discuss some of the newest and most promising ones. Hydrogen Fuel Cells: One of the most exciting developments in locomotive fuel is the use of hydrogen fuel cells. These fuel cells work by converting hydrogen and oxygen into electricity, with water as the only byproduct. Hydrogen fuel cells have been tested in several locomotives, and the results have been very promising. They are a sustainable and clean source of energy that produces zero emissions, making them an ideal choice for locomotives. Battery-Electric Locomotives: Battery-electric locomotives are another technology that is being tested in the locomotive industry. These locomotives use rechargeable batteries to power electric motors, which in turn power the train. The batteries can be charged using renewable energy sources, making this technology a sustainable option. Battery-electric locomotives have already been used in several short-haul and light-rail applications, and there is a growing interest in developing them for heavier freight trains. Natural Gas: Natural gas is another fuel that is being tested in the locomotive industry. Natural gas is a cleaner burning fuel than diesel, and it produces fewer emissions. It is also cheaper than diesel, making it an attractive option for locomotive operators. Several locomotives have already been converted to run on natural gas, and the results have been positive. Biofuels: Biofuels are another sustainable option that is being tested in the locomotive industry. Biofuels are made from renewable sources, such as vegetable oils or animal fats. These fuels produce fewer emissions than diesel, making them a cleaner alternative. Biofuels have already been tested in several locomotives, and they have shown promising results. Hybrid Locomotives: Hybrid locomotives are another technology that is being developed in the locomotive industry. These locomotives use a combination of two or more power sources, such as diesel and electric power, to run the train. The goal of hybrid locomotives is to reduce emissions and increase fuel efficiency. Several hybrid locomotives have already been developed and tested, and the results have been positive. The technologies discussed in this article are just a few of the many being tested. As the world moves towards a more sustainable future, it is important that the locomotive industry adapts and finds ways to reduce their environmental impact. By investing in sustainable technologies, the industry can reduce emissions, save money, and provide a cleaner and more sustainable future for all.

March 1, 2023

Train travel has been a popular mode of transportation since the 19th century, and it continues to be widely used today. However, despite advances in technology and safety measures, train accidents have occurred throughout history, resulting in tragic loss of life and devastating damage. There is News everywhere about the environment problem in OHIO and now the crash in Greece. Major train accidents in history Quintinshill Rail Disaster (1915) On May 22, 1915, the deadliest train accident in British history occurred at the Quintinshill railway station in Scotland. Two passenger trains collided, and a third train crashed into the wreckage. A total of 227 people were killed and more than 246 injured. Saint-Michel-de-Maurienne Train Disaster (1917) On December 12, 1917, a train carrying French soldiers derailed in Saint-Michel-de-Maurienne, France, killing at least 540 people and injuring hundreds more. The accident was caused by a combination of excessive speed and poor maintenance. Balvano Train Disaster (1944) On March 2, 1944, a train carrying hundreds of people stalled in a tunnel near Balvano, Italy. Due to the lack of ventilation and the use of coal-fired engines, many passengers died from carbon monoxide poisoning. The exact number of casualties is unknown, but estimates range from 426 to 500. Tsurumi Train Disaster (1963) On November 9, 1963, a train carrying more than 1,000 passengers derailed in Tsurumi, Japan, killing at least 161 people and injuring more than 300 others. The accident was caused by a broken axle on one of the train's carriages. Tangshan Train Disaster (1976) On July 28, 1976, a train carrying more than 1,000 people derailed near Tangshan, China, killing at least 200 passengers and injuring many more. The accident was caused by a combination of human error and poor maintenance. Bihar Train Disaster (1981) On June 6, 1981, a train carrying more than 800 passengers derailed in the Indian state of Bihar, killing at least 800 people and injuring hundreds more. The accident was caused by a combination of overcrowding, poor maintenance, and human error. Awash Train Derailment (1985) On January 6, 1985, a train derailed in the Awash River valley in Ethiopia, killing at least 428 people and injuring hundreds more. The accident was caused by a combination of poor maintenance and excessive speed. Gare de Lyon Train Accident (1988) On October 27, 1988, a commuter train crashed into a stationary train at the Gare de Lyon railway station in Paris, France. The collision sparked a fire that killed 56 people and injured more than 100 others. Ufa Train Disaster (1989) On June 4, 1989, two passenger trains collided near Ufa, Russia, killing at least 575 people and injuring hundreds more. The accident was caused by a combination of human error and a faulty signalling system. Santiago de Compostela Derailment (2013) On July 24, 2013, a high-speed train derailed near Santiago de Compostela, Spain, killing 80 people and injuring more than 140 others. The accident was caused by excessive speed, with the train travelling at more than twice the speed limit. In next articles we will explore the major causes of accidents and what to do to help avoid them.