The Importance of Isolated Joints in Track Circuits

Railways have been a backbone of transportation for centuries, and in modern times, technology has transformed the rail industry, making it safer, more efficient, and reliable. One crucial aspect of railway signaling and train detection systems is the use of track circuits. Within these track circuits, isolated joints play a vital role in ensuring the accurate and reliable detection of trains on the tracks. In this article, we will explore the importance of isolated joints in track circuits for rail applications.

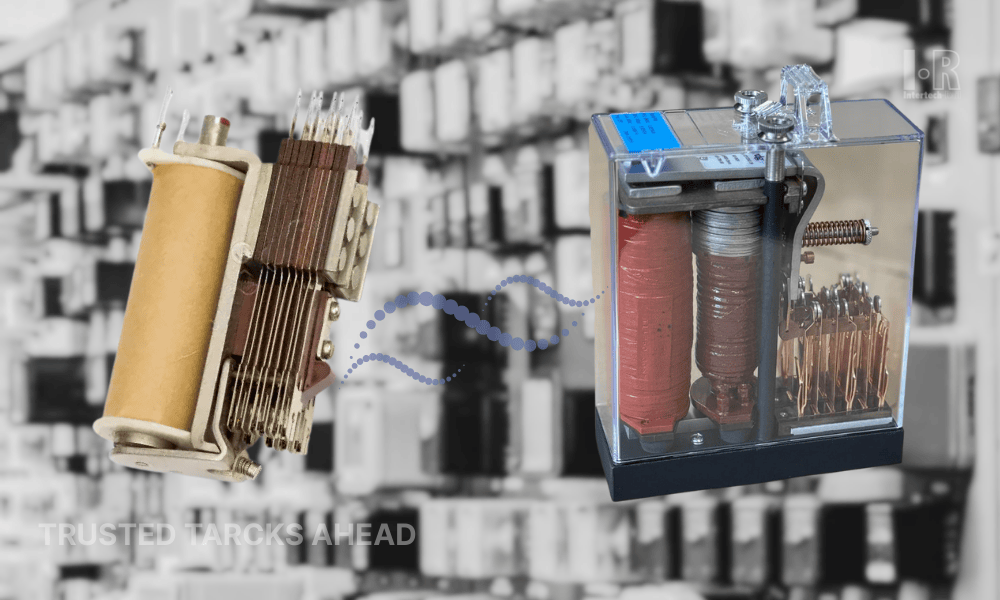

Track circuits are an essential part of railway signaling systems used to detect the presence and location of trains on a given section of the track. They work on a simple principle: when a train moves over a section of track, it short-circuits an electric current that flows through the rails. The disruption caused by the train's presence is detected by track circuit controllers, which then signal the status to the railway control center, indicating that the section of track is occupied.

Crucial purposes of Isolated Joints

Isolated joints are designed to electrically isolate specific rail sections from each other. These joints create electrical gaps in the track, ensuring that the current cannot flow freely across the entire stretch of rails. Instead, the track is divided into discrete blocks or sections, each with its own track circuit. This isolation is critical for the proper functioning of the signaling system, and it serves several crucial purposes:

Precise Train Detection

By isolating the track into blocks with isolated joints, train detection becomes more accurate and reliable. When a train moves over a track section with isolated joints, it completes the circuit and causes a noticeable change in electrical characteristics, clearly indicating its presence. This information is crucial for train control and helps prevent accidents by ensuring that trains are detected in real-time, allowing for safe distance control between trains.

Simplified Maintenance

Isolated joints simplify the maintenance process by allowing the rail infrastructure to be divided into manageable segments. If a section of track requires repair or maintenance, it can be isolated without affecting the entire rail network. This reduces downtime and enhances the overall efficiency of rail operations.

Redundancy and Safety

Isolated joints also contribute to the overall redundancy and safety of the track circuit system. If a joint or a section of track becomes damaged or fails, only that particular section will be affected. The rest of the track circuit will continue to function, allowing train detection to occur in adjacent sections without disruption.

Electrical Noise Reduction

Railway tracks are subject to various electrical interferences, such as stray currents and electromagnetic interference. Isolated joints help mitigate these issues by limiting the extent to which electrical currents can flow through the track. This ensures a clearer signal for train detection, reducing the likelihood of false positives or negatives.

As the rail industry continues to evolve and embrace advanced technologies, the proper design, installation, and maintenance of isolated joints will remain crucial to maintaining a safe and dependable rail network for passengers and freight alike.