Intertech Rail develops the IRX specifically for level crossings of heavy vehicles (mining), conventional vehicles, pedestrians and cyclists, train stations, stops, depots, and industrial plants. The panels have innovative design with savings of 30% weight when compared to similar in the market, still ensuring the same or superior performance in moderate and heavy loads.

Advantages

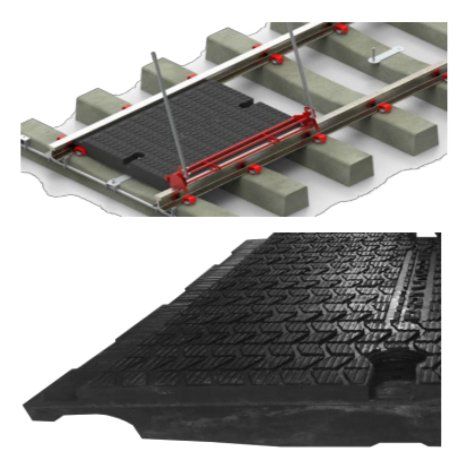

The modular system consists of individual vulcanized rubber panels, which are handled with a metal locking system that can be adapted to any type of rail and sleepers.

An additional feature is a rhomboid-shaped pattern with triangular tips that optimize traction and performance in rainy conditions, achieving particularly fast drainage and excellent non-slip properties.

COMPONENTS

The modules are fully formed by a mixture of vulcanized components together that ensures a suitable weight for easy handling and installation.

- High inner panel for rail block, illuminated in vulcanized rubber (40% Virgin-60% recycled rubber). Total weight 158 kilos.

- High outer PANEL for 75LBY rail. Lightweight block in vulcanized rubber (40% virgin rubber-60% recycled rubber). Total weight 85 kilos.

- Beam A: 312mm wide, 1200mm long, 325mm high; 300 PSI compact beam concrete, total weight 204 kilos. This beam allows the top lock of the external modules.

All metal components are in RH A36 cold galvanized steel.

Total linear meter weight: 257.4 KILOS

IMPORTANT DETAILS

Aesthetics: It improves the appearance of the level crossing because its color is apparently

similar to asphalt, in addition to producing smoothity and safety for the person at the time of crossing.

Load capacity: Thanks to the combination of loads carried out by the containment of all elements (modules, containment beams and sleepers) the loads are evenly distributed towards the ground, thus avoiding the displacement of the railway.

Cost: Non-slip rubber coating has a lower overall cost than other materials (concrete, wood, welded rails, etc.) if we compare its durability, installation, and maintenance easily.

Service life: 10 to 30 years, Second workload

INSTALLATION

Traffic should flow quickly and without complications, making it faster in terms of planning, construction and maintenance, since it takes only 5 hours to assemble the modules of a level step of 12 meters and no heavy machinery. For a faster installation, 3 operators are required for heavy machinery (forklifts), but only 3 hours of assembly. For road renovation work, modules can be dismantled and reinstalled at any time and without complications;

The installation of the non-slip rubber floor is quite simple. Once the spacing between the sleepers (60cm) has been checked and the track has been struck, it is filled with ballast to the top of the sleepers and is marked halfway to the level that should match the center of one of the sleepers. Immobilizer clips are mounted in the center and ends and clamps with coupling at the joints of the modules ensuring the firmness of any step in the level. A special tool is used to install the internal modules to push the end of the module to the rail head.

The external modules are supported by the transverse beam and the containment girder assembly and previously adjusted.

TECHNICAL DATA

Our products are durable and reliable and withstand all kinds of climatic conditions thanks to their unique mixing design and integration. High-tech components ensure excellent resistance to shock, wear, aging and loss performance.

50% rubber composition does not splinter, disintegrate or crack by subjecting to heavy loads due to the vulcanization process to which all our products are subjected.

RESISTANCE

Abrasion and wear resistance. It has good acoustic absorption properties, very good resistance to atmospheric agents and temperature changes.

- Rhomboid-shaped grip pattern with triangular tips that optimize traction and performance in rainy conditions, achieving particularly fast drainage and excellent non-slip properties.

- The SRV value (standardized value for measuring slip resistance in wet conditions) is equal to that obtained with asphalt; Beveled edges protect the contour of modules above all in heavy loads.

1501 Venera ave Suite 320A Coral Gables, FL 33146

+55 11 985974011 (Brazil)

+1 614 302 1900 (USA)

Intertech Rail 2024 - All Rights Reserved