Artificial Intelligence In Railway Automation

At a certain cement plant near the city of Baku in Azerbaijan the directors were facing a real crisis with their suppliers. Every day railway compositions arrived with Clay or Calcáreo from various suppliers but using the trains of the factory itself that went to the mines to be loaded.

There was an employee who, on the approach of the train, typed into the system what materialwas carrying you, simply looking at the cargo. But depending on daylight, schedule, rains, clay and calcáreo look a lot like. And there was the problem.

Our company was called to decide which ore the wagons were transporting and pesar the material at the entrance and exit thus determining the net weight that was delivered to the factory on a given day and time.

Three Technologies for Wagon Identification

AEI - Automatic Equipment Identification

To enable wagon identification, a Reader and one RFID Antenna were installed alongside the track. Additionally, an RFID tag was affixed to each locomotive and wagon. This ensured that the wagons could be identified both upon entry and exit from the system.

Use of Railway Scales

Thus the entry and exit weight is measured and attributed unequivocally to the given wagon read by RFID reader.

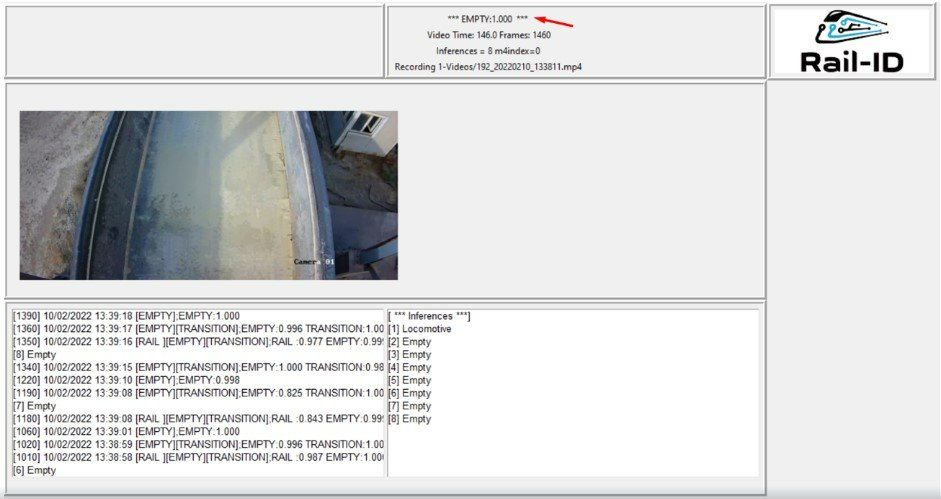

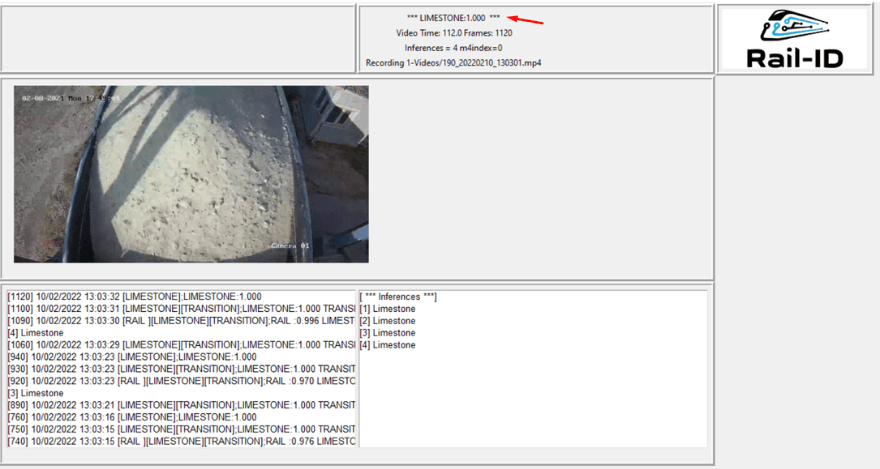

Artificial Intelligence for Image Recognition

Artificial Intelligence as well as Image Recognition have been used in various technology sectors for various purposes such as identifying people, identifying parts in the industry and entering the railway sector to recognize the ore transported in certain wagons.

Positioning a camera at the top of the rail, hours and hours of videos were collected from the circulating trains and these images were introduced and registered in the system so that the NeuraL Network could be trained and recon the main structures of interest to the solution.

Among the structures, the system was trained to identify and recognize in the image RAIL (only rails), LOCOMOTIVE (Locomotives), CLAY(clay) and LIMESTONE (calcáreo) TRANSITION (Transitions between two wagons) and EMPTY( empty). For each image the system assigns a scale from 0.000 to 1,000 where 0,000 the searched structure is nonexistent and 1,000 is 100% sure that it is present in the image. For precision purposes, the structure with a scale greater than 0.800 (80%) was considered existing.

The system still manages, also through artifical intelligence, to understand the decay in neural network learning (because the lenses are out of position or increased dirt or changed the lighting a lot in a given season of the year) and self-train to increase the level of identification.

In this way, it is possible to recognize with extreme precision, which load each wagon carries, with much greater precision than the human eye. By integrating the three modules (AEI, weighing and image recognition) it is possible to determine the net weight of the load delivered at the factory.

Multiple levels of automation, along with AI and a problem solved.

Sample Tables

Figure 1

Example of Table generated by the system identifying material, date, time of entry and exit and net weight

Figure 2

System recognizes the presence of the RAIL structure (rail only)

Figure 3

System recognizes the presence of locomotive structure (Locomotive) and TRANSITION (a transition to a wagon is taking place)

Figure 4

System recognizes the presence of the Structure LIMESTONE (Calcáreo)

Figure 5

System recognizes the presence of clay structure