ATW – Automatic Train Warning

Much is said about Railway Automation. Automation, in all fields, is the optimization of processes, mainly human and mainly to increase productivity.

Safety before productivity.

We at

INTERTECH RAIL separate railway automation into two parts:

railway automation itself and railway or rolling stock automation.

Railway Automation:

In the case of railway automation, the keyword is signaling. It has to do with a lot of safety and a lot of reliability in the equipment.

Terms like FAILSAFE are mandatory on all equipment and mean that if there is a failure, it must occur safely, avoiding accidents.

Failsafe equipment is actually much more expensive than equipment that is not failsafe. Therefore, there is failsafe in a

level crossing.

Any problem that happens, power outages, equipment breakdown or lack of communication, must happen with the barrier down, it can never happen with the barrier up. Any equipment that breaks down must enter a safe state.

So, it is the automation of the railway, whose signaling indicates occupation of the train ahead, so that the locomotive behind can reduce speed or even brake so as not to enter the stretch occupied by a train ahead.

Thus, when a railroad is fully signaled, the driver's stress is reduced to almost zero, as he only has to follow the railroad signal that he will be in a safe state. He doesn't need to keep an eye on the maximum attention, looking ahead to check if he has something, because

the automation of the railway is independent, it works through interlocks that do not depend on human action, so the safety level is very high.

Train automation:

It has to do with not relying so much on human operation.

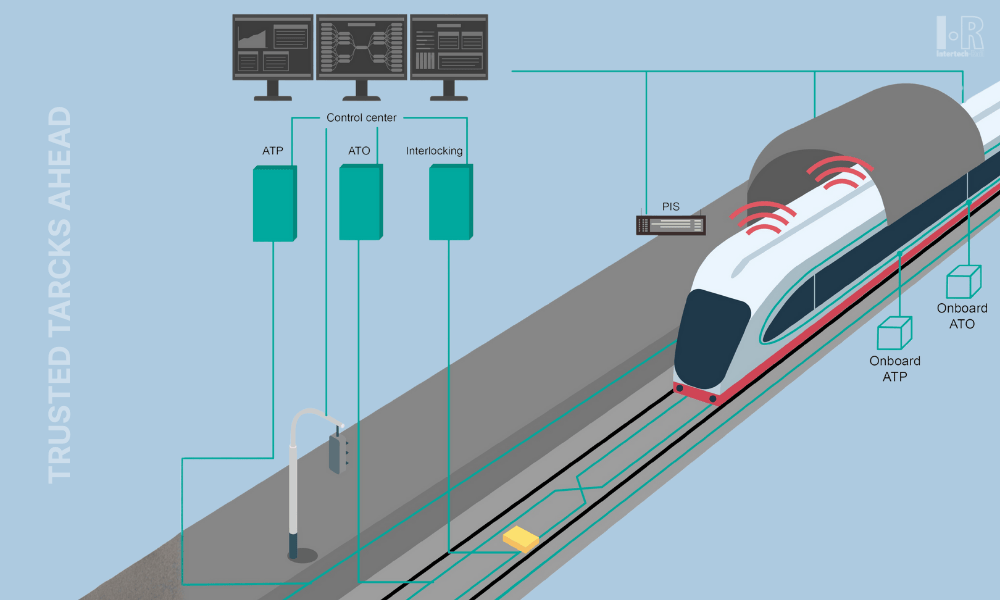

The train performs actions based on local and remote processing, computers and we call it onboard automation. And then there's an alphabet soup associated with it:

ATS, ATP, ATC, which is basically the

automatic train STOP.

An example is when the train passes a red light, if the conductor does not stop, the train will stop by itself. An

RFID (Radio Frequency) tag (beacon) (Identification) installed on the sleeper “notifies” the on-board computer of the signalman's status and the emergency brake is applied.

The

“Automatic Protection of the Train”, where the train receives information from these same beacons that inform the maximum speed in that section. for example, if it is 80 km/h and there is a section where the maximum is 30 km/h, the conductor must decelerate, if not , the train decelerates automatically.

And the maximum level is the ATC, “Automatic Train Control”, which is the train actually driving, the conductor acts only in an emergency, the operation is fully automated and the installed beacons inform the train's position, maximum speed and minimum, the signaling on the track, and the computers that are connected to the control center, warn if there is occupation ahead, so that the train travels fully automatically. When arriving at a station, there are many beacons that make the train stop in the exact position with an error of a few centimeters, to open doors on the subway, for example.

However, there is an intermediate level, which is becoming increasingly common on railways around the world, called

ATW (Automatic Train Warning).

How does the ATW (Automatic Train Warning) system work? It

does not interact with the locomotive, but provides information to the driver about the environment where the

railway is located. If there is any kind of accident ahead, men working, if there is a need to slow down, if there is an indigenous village, level crossing, then the system, through beacons also located in the event area, inform the ATW system (a simpler on-board computer) that processes the information, stores it and passes it on to a video (HMI) that informs the driver what is happening, what is approaching.

The driver must sometimes take action, press a button, confirm that he is aware of the employees close to the highway working, say that he is aware that the maximum speed on that stretch is 30 km/h.

With the ATW, the “railroad operator” can inform the driver of what is happening on his way without relying on radios, but in a much more economical way mica than an ATC or even ATP.

There is no protection that prevents the driver from acting on his own, as the ATW does not interact with the locomotive engine, but at the same time it is informative that requires

the driver's attention and increases safety in a way accessible mainly for railways. minors miners.

Again, in situations such as approaching level crossings, men working or accident on the road, needing to reduce speed, recent renovations or bumps to wait for geometric defects in the road that have not yet been corrected, all of these can be quickly placed in a beacon at that time. stretch and the driver is informed and must interact with the interface to alert the event.

Low-cost security

ATW has been widespread on railroads with limited resources for full automation and even on railroads with little signage. It is an economical solution that manages to provide an intermediate level of safety and is often quite satisfactory to avoid an accident. In that sense, it is a great benefit at low cost.